If you’ve ever worked around packaging machines or inside a pharma plant, you already know one thing-nothing works properly without a stable vacuum. And honestly, most machines depend so much on the vacuum system that even a small drop can mess up the entire process. This is exactly where Rotary Vane Pumps quietly become the real MVP.

They’re not flashy, they’re not complicated, but they work every single day without creating drama. And frankly, that’s all factories want-machines that don’t get moody.

Why Rotary Vane Pumps Are Such a Big Deal

Let’s be honest, most people don’t care “how” vacuum is created. They only care that the vacuum doesn’t fluctuate.

Rotary Vane Pumps are loved because they give a stable vacuum without acting unpredictable.

They’re known for:

- Reliable vacuum levels

- Smooth operation

- Low maintenance

- Long running hours

Basically, you switch them on, and they mind their own business.

And industries absolutely love that.

So, How Do They Even Work?

By the way, the working style of Rotary Vane Pumps is surprisingly simple. Inside the pump, a rotor spins. On this rotor, small vanes slide in and out. When the rotor turns, the vanes trap air and push it out of the pump, creating vacuum inside the chamber.

No rocket science. No complex engineering. Just a neat little mechanism that keeps going.

Because the system is so simple:

- It doesn’t break often

- It doesn’t use crazy amounts of energy

- It stays stable even under load

- It handles moisture better than many pumps

And that’s why most technicians say, “Rotary Vane laga do, problem hi khatam.”

Why Packaging Units Prefer Rotary Vane Pumps

Let’s be real here-packaging lines run super-fast. Thousands of packets go through the sealing line, and every packet needs the perfect vacuum. Even the slightest dip can ruin the seal.

That’s why Rotary Vane Pumps fit perfectly.

They help packaging units achieve:

- Cleaner and tighter sealing

- Faster cycle times

- Lower wastage

- Better shelf life for products

From chips to biscuits to medical pouches pumps keep the vacuum steady.

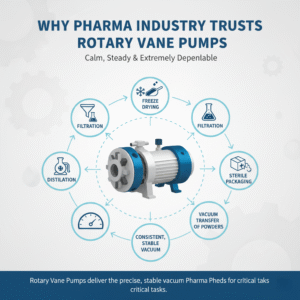

Why Pharma Industry Trusts Them Even More

Pharma isn’t like normal manufacturing. Here, everything has to be exact—no guesswork, no shortcuts.

And Rotary Vane Pumps fit right in because they’re calm, steady and extremely dependable.

Pharma teams use them for:

- Freeze drying

- Filtration

- Distillation

- Sterile packaging

- Vacuum transfer of powders

These tasks need a vacuum that doesn’t jump around, and that’s exactly what rotary vane systems deliver.

Real Advantages That Make Them Industry Favourites

I won’t complicate it. Here’s the simple, real-world stuff:

1. Consistent Vacuum

No sudden fluctuations, no performance mood swings.

2. Low Noise

You can literally stand next to one and still have a conversation.

3. Easy to Maintain

Change the oil, check the vanes—done.

4. Compact Design

They don’t eat space in crowded factory floors.

5. Long Life

Most rotary vane units run for years before giving any trouble.

6. Cost-Friendly

Great performance without burning a hole in the company’s budget.

Industries don’t want fancy-they want dependable. Rotary Vane Pumps give exactly that.

Where Other Pumps Lose the Game

- Some pumps get noisy.

- Some get hot too fast.

- Some choke when moisture enters.

- Some lose suction pressure randomly.

But rotary vane pump systems?

- They just keep running.

- They don’t complain, they don’t get stressed, they don’t overreact.

- They’re almost like that one employee who silently does all the work without showing off.

A Simple Example (You’ll Relate)

Imagine a biscuit packaging line. Everything is fast. If the vacuum slips, packets won’t seal properly. One small issue and you’ll see a pile of rejected packets.

Now imagine a pharma lab where they’re doing freeze drying. If the vacuum isn’t steady, the entire batch may get wasted.

In both cases, Rotary Vane Pumps save the day by keeping things rock-steady.

Final Thoughts

At the end of the day, industries choose Rotary Vane Pumps because they’re stable, quiet, strong and trustworthy. They don’t complicate things-they make work easier. Whether it’s packaging or pharma, no one wants to deal with vacuum issues. And with rotary vane pumps, they rarely have to.

Sometimes the simplest machines are the ones that carry the whole process. Buy now!

FAQs

- Why are Rotary Vane Pumps popular in packaging?

Because they give rock-steady vacuum for perfect sealing. - Do they need heavy servicing?

Not at all. A quick oil check and they’re good. - Can they run non-stop?

Yes, they’re built for long continuous operation. - Are Rotary Vane Pumps good for pharma use?

Absolutely. They work clean, quiet and very stable. - Do they save energy?

Yes, their simple design uses less power compared to bulky pumps.

Follow us on Facebook for more industrial insights and tech updates.

Subscribe to our YouTube channel for the latest industrial guides, tech insights, and how-to videos.