Applications of SS Barrel Pumps – Let’s be honest, nobody enjoys handling liquids manually in big factories. Whether it’s chemicals or food products, the real headache starts the moment you have to transfer liquids safely without wasting time or creating a mess. And that’s exactly where SS Barrel Pumps quietly save the day. In fact, once industries start using them, they never go back to old-school methods. When we talk about Applications of SS Barrel Pumps, the list is actually long.

But today, we’re keeping it simple and looking at the top 10 uses that genuinely matter in chemical and food industries.

Why Applications of SS Barrel Pumps Are a Big Deal

Before jumping into applications of SS Barrel Pumps, let’s be real for a moment. SS pumps are popular because they solve real problems.

They’re clean, durable, smooth, and they never react with the liquids inside the barrel. By the way, stainless steel pumps handle everything from thin liquids to slightly viscous materials without making a fuss.

Plus, workers love them because they reduce effort, save time, and prevent spills. Companies love them because they cut losses. Everyone wins, basically.

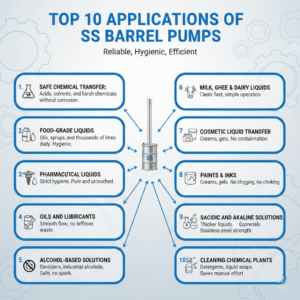

Top 10 Applications of SS Barrel Pumps

1. Safe Chemical Transfer

When you deal with acids, solvents, or harsh chemicals, you can’t take risks. One wrong move and things get messy.

Here, Applications of SS Barrel Pumps become super useful because these pumps handle aggressive chemicals without corroding or reacting.

2. Transferring Food-Grade Liquids

From oils to syrups, food units move thousands of litres daily. SS pumps keep everything clean and hygienic.

By the way, the stainless-steel body ensures no contamination.

3. Handling Pharmaceutical Liquids

Pharma industries follow strict hygiene rules. SS pumps fit right in because they keep liquids pure and untouched.

4. Moving Oils and Lubricants

Lubricant manufacturers use SS pumps all the time. The flow stays smooth, and the barrel gets emptied without leftover waste.

5. Transferring Alcohol-Based Solutions

Whether it’s sanitizers or industrial alcohols, SS pumps move them safely. No spark, no reaction, no tension.

6. Handling Milk, Ghee & Other Dairy Liquids

Let’s be honest, dairy products can get messy fast. SS pumps make the operation clean, fast and simple.

7. Cosmetic Liquid Transfer

Creams, gels, lotions—cosmetic units handle all sorts of liquids. SS pumps keep them safe from contamination and ensure consistent flow.

8. Moving Paints & Inks

Even though paints are thicker, SS pumps handle them surprisingly well. No clogging and no choking.

9. Acidic and Alkaline Solutions

Chemical plants rely on SS pumps for corrosive materials because stainless steel stays strong even with continuous exposure.

10. Transfer in Cleaning Chemical Plants

Detergents, cleaners, liquid soaps-all these flow smoothly through SS pumps. Frankly, these pumps save a lot of manual effort.

Why Industries Trust SS Barrel Pumps

Let’s be real-industries don’t buy equipment because it “sounds cool.” They buy it because it works without drama.

Here’s why SS barrel pumps are a favourite:

- Easy to operate

- Fast transfer speed

- Hygienic and contamination-free

- Long life due to sturdy steel

- Safe for chemicals and food

- Low maintenance

- Consistent flow

- No complicated setup

When you look at all these points, it’s clear why Applications of SS Barrel Pumps are growing everywhere-from small units to giant factories.

Real-World Impact You Can’t Ignore

One thing I’ve noticed is that companies switch to SS barrel pumps mainly because they want safety and speed.

And frankly, that’s the smart thing to do. Manual transfer leads to spills, wastage, worker fatigue, and safety risks. SS pumps cut down all that hassle.

Whether you run a small production line or a full-scale manufacturing plant, these pumps quietly make life easier.

Final Thoughts on Applications of SS Barrel Pumps

At the end of the day, the real strength of SS barrel pumps lies in their simplicity. They don’t try to be fancy-they just do the job cleanly, quickly and consistently. And that’s why the Applications of SS Barrel Pumps in chemical and food industries keep growing every year.

Once industries switch to SS pumps, they stick with them for good. Shop now!

FAQs

- Are SS barrel pumps safe for chemicals?

Yes, totally. They handle harsh chemicals without reacting. - Can these pumps transfer food liquids?

Absolutely. They keep everything hygienic and contamination-free. - Do SS pumps need heavy maintenance?

Not really. Basic cleaning and they run smoothly. - Are they good for thick liquids like syrups?

Yes, they handle semi-viscous liquids easily. - Why are industries shifting to SS barrel pumps?

Because they’re safer, cleaner and way more reliable than manual transfer.

Follow us on Facebook for more industrial insights and tech updates.

Subscribe to our YouTube channel for the latest industrial guides, tech insights, and how-to videos.